When the non-linear load characteristics of a VFD cause the electrical supply waveform to deviate from a pure sinusoidal shape, this is called harmonic distortion in VFD. The main cause of this distortion is the VFD’s use of a bridge rectifier to convert AC to DC power, which draws current in pulses rather than gradually. These pulses generate harmonic currents that distort the voltage waveform when combined with the fundamental frequency.

What is meant by Harmonic Distortion?

In a power system, harmonic distortion in VFD occurs when undesired frequency components are present. These undesirable elements can have a major effect on the power system’s dependability and performance. They are integer multiples of the fundamental frequency, which is often 50 or 60 Hz.

What Causes Harmonic Distortion in VFD?

Power systems can experience VFD harmonics distortion for several reasons, which can be roughly divided into the following categories that are related to energy efficiency:

1. Non-linear loads:

The existence of non-linear loads is the main contributor to harmonic distortion. Because of the non-sinusoidal current demand of these loads, the current waveform is distorted. Non-linear loads include power electronic devices such as rectifiers, inverters, and adjustable speed drives, as well as electronic equipment such as computers, LED lamps, and fluorescent lights. The switching processes of these devices produce harmonics in VFD drives, which have the potential to spread throughout the electrical system

2. Electrical Power Devices:

Power electrical equipment, such as converters and inverters, is are major generator of harmonics, as was previously noted. These devices’ quick switching processes have the potential to produce high-frequency harmonics that spread throughout the system. Inter harmonics, which are non-integer multiples of the fundamental frequency, can also be introduced by the control algorithms utilized in these devices.

3. Saturation by Magnetic Field:

Harmonic distortion can also result from magnetic saturation in transformers and other inductive devices. Harmonics are produced when a transformer’s magnetizing current becomes nonlinear due to saturation. This phenomenon is more likely to happen when the transformer is over voltaged or when there is a large load.

4.In tune:

Resonance can occur when one or more harmonic frequencies coincide with the intrinsic frequency of a power system. The levels of harmonic distortion may rise sharply as a result of harmonic amplification.

Transmission lines, transformers, and capacitor banks are examples of inductive and capacitive parts of the system that might interact to produce resonance.

5. Problems and Unbalanced Situations:

Asymmetrical circumstances, such as unbalanced loads or faults, like short circuits, can also result in harmonic distortion. Harmonics may be produced by non-sinusoidal currents and voltages caused by these circumstances.

Signs of Electrical System Harmonic Issues

The symptoms of harmonic issues may be further divided into three major categories:

Equipment malfunctions and malfunctions

Examples of equipment malfunction and failure linked to harmonics on a power supply include the following symptoms:

- Motors, wires, transformers, and neutrals that are overheating

- Vibrations in the motor

- Transformers and whirling machinery make audible noises.

- Operation of the nuisance circuit breaker

- Fires caused by electricity

- Notching of voltage

- Operation of electrical equipment that is erratic

- Lockups of computers and/or PLCs

- Faulty voltage regulator

- Errors in timing or digital clocks

- A faulty generator regulator

- Flickering LED lights

Economic factors

When evaluating harmonics, the following economic factors should be taken into account:

- Inefficiencies and losses (motors).

- kW losses in transformers and cables.

- Low power factor overall.

- Generator dimensions.

- UPS dimensions.

- Issues with capacity (transformers, cables).

- The utility imposed fines.

Capacitors for power factor adjustment

Using power factor correction capacitors requires paying close attention to harmonics:

- Capacitor malfunctions.

- Tripping of a fuse or breaker (feeding capacitors) is an inconvenience.

- Harmonic resonance conditions, either observed or computed (series or parallel resonance).

When and Where Do Harmonic Problems Show Up?

Here’s a more thorough explanation related to harmonic distortion in VFD:

When Harmonic Problems Show Up

- In the presence of non-linear loads, Harmonics are produced when certain loads—such as variable frequency motors, computers, LED lights, and welders—draw electricity in non-sinusoidal waveforms.

- When the neutral conductor’s capacity is inadequate, in three-phase systems with single-phase loads, triplen harmonics—multiples of the third harmonic—can result in a sizable current in the neutral.

- At the moment of resonance, the impacts of harmonic currents can be amplified when they resonate with other parts of the system, such as capacitors.

- When there are disruptions in the system, Harmonic problems can be made worse by transient occurrences (like voltage sags or spikes).

Where Do Harmonic Problems Show Up

- Transformers: Triple harmonics can cause the neutral conductor to overheat and fail.

- Connectors and Wires: increased skin effect-induced heating and insulation degradation, particularly in neutral conductors.

- Motors: vibration, overheating, and shortened lifetime.

- Circuit Breakers: harm potential and nuisance tripping.

- Devices for Electronics: Lockups, irregular behavior, and malfunctions.

- UPS systems and power supplies: overheating, shortened lifespan, and possible failure.

- Generators: voltage notching, regulator errors, and possible instability

Preventive Checks to Identify Harmonic Distortion

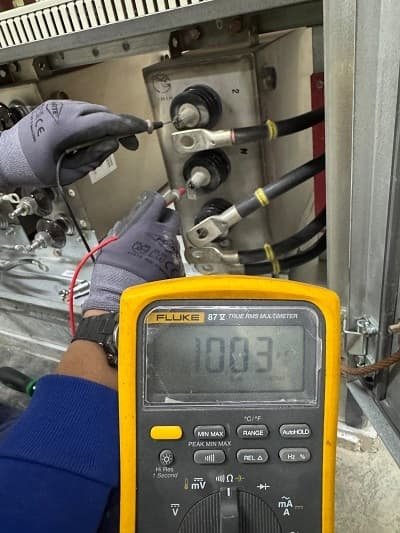

It is crucial to check for harmonic distortion in VFD systems before faults occur. The following preventive checks can help:

- Measure the Total Harmonic Distortion (THD) when installing a new capacitor bank to avoid equipment damage.

- Conduct a harmonics assessment to identify if distortion is causing frequent capacitor bank issues.

- Inspect installations with random circuit failures to determine if harmonics are the reason.

- Check discharge lighting in industrial facilities, as non-linear loads can introduce harmonics even without active production.

- Measure electrical controls in air conditioning and cooling systems, since cold storage facilities are often vulnerable to harmonic currents.

For LV VFD and MV VFD services, schedule regular inspections to ensure compliance with power quality standards and minimize harmonic risks.

Negative Effects of Harmonics on Industrial Operations

Particular adverse impacts related to harmonic distortion in VFD:

- Overheating of Equipment: Harmonics increase current and eddy losses in cables, transformers, and motors, causing overheating and possible fire risks.

- Early Equipment Failure: Voltage distortions and mechanical stress accelerate wear, leading to higher maintenance costs.

- Enhanced Energy Dissipation: Extra losses in conductors and transformers raise energy consumption.

- Rotating Machine Vibrations: Torque pulsations create vibrations that damage bearings and reduce motor life.

- Voltage Notching and Distortion: Sensitive electronics may malfunction due to waveform distortion.

- Economic Impact: Increased energy bills, downtime, and equipment failures cause financial losses

- Safety Hazards: Overheating and failures raise the risk of shocks and fires.

How to Fix Harmonic Problems After Diagnosis

After diagnosing harmonic distortion in VFD issues, consider the following fixes:

Use multi-pulse VFDs to minimize harmonic generation.

Install passive harmonic filters for simple, cost-effective mitigation.

Apply active harmonic filters for dynamic and more accurate correction.

Add AC line reactors to smooth current flow and reduce harmonics.

Effective mitigation requires selecting the right technique based on the electrical system and the specific harmonic problems identified.

Design Recommendations to Prevent Harmonics in New VFD Systems

Several design suggestions should be taken into account to reduce harmonics in new VFD systems:

- Do harmonic analysis early in the design stage to detect problems.

- Use active or passive harmonic filters depending on load conditions.

- Consider multi-pulse VFDs (12 or 18-pulse) to reduce harmonic generation.

- Install line reactors or DC link reactors for additional harmonic reduction.

- Apply phase-shifting or isolation transformers to minimize disturbances.

- Choose proper system grounding to enhance stability.

- Select VFDs and equipment with low harmonic emission.

- Distribute non-linear loads strategically.

- Ensure compliance with IEEE 519 standards.

- Monitor harmonic levels continuously with power quality systems.

- Perform regular maintenance and inspections.

By applying these steps, harmonic distortion in VFD systems can be minimized, ensuring reliable and efficient operation.

Reducing Harmonic Distortion in Industrial Applications

Ways to Lower Harmonic Distortion in VFD in Power Systems that depend on Industry

- Harmonic filters that act actively: Active harmonic filters (AHFs) generate counter-harmonic currents to cancel system harmonics.

- Harmonic filters in a passive manner: Passive filters block specific harmonics at fixed frequencies, effective for steady loads.

- Harmonic Mitigation Technology in Variable Frequency Drives (VFD): Modern VFDs come with built-in harmonic mitigation features, reducing distortion while controlling motors.

- Converters that are 12- and 18-pulse: These converters produce fewer harmonics than standard 6-pulse rectifiers.

- Shifting phases and transformers: Phase-shifting transformers reduce targeted harmonics by altering phase angles.

- Enhancing Load Control and System Architecture: Good system design and balanced load distribution minimize harmonic distortion long-term.

Need Help with VFD Harmonics?

A hybrid power quality compensator, R-aletqan, integrates two current technologies into a single, small, and effective unit. An active harmonic filter and a bank of detuned capacitors form the basis of its functioning.

The majority of capacitive reactive power requirements are satisfied by the detuned capacitor stages. In the meanwhile, the Harmonic Filter module filters the harmonic currents, balances the imbalanced currents, and manages the intermediate steps and inductive reactive power.

R-aletqan is a complete power quality system. Give us your contact information, and our engineers will assist you in locating the answer you want.

FAQ

What is the THD level of VFD?

A variable frequency drive’s (VFD) total harmonic distortion (THD) level often falls between 30% and 80%.

Do all VFDs cause harmonic distortion?

Indeed, harmonic distortion is a natural byproduct of variable frequency drives (VFDs).

How can I reduce THD caused by VFDs?

Adding line reactors, utilizing passive or active harmonic filters, and putting multi-pulse VFDs into place are a few possible approaches.