A well-structured VFD preventive maintenance checklist is essential for keeping your drives operating at maximum efficiency. With variable frequency drives (VFDs), preventive maintenance is essential to maintaining your equipment in optimal working order. These devices are significant investments; therefore, maintaining their functionality is essential to earning a healthy profit.

To keep expenses down and ensure reliable performance, you may lower your chance of malfunctions and avoid expensive repairs by sticking to a regular preventative maintenance program.

Purpose of Using VFD

VFDs are primarily used to control the speed and torque of electric motors based on actual process demands. By adjusting the motor’s speed, VFDs help reduce energy consumption, minimize mechanical stress, and improve overall system performance. Their ability to match motor output to load requirements makes them essential in industrial applications where energy efficiency and process precision are critical.

A Basic Overview of VFD Structure

The architecture of a VFD is a combination of efficiency and complexity. Fundamentally, the VFD’s job is to efficiently control electrical power so that the motor runs at the speeds that are intended. To regulate the motor speed, these (the rectifier, DC bus, and inverter) parts cooperate to transform incoming AC power into a variable frequency output.

Gaining an understanding of this fundamental structure is essential to understanding how VFDs improve motor performance and energy economy.

Benefits of Preventive Maintenance for VFDs

Regular VFD Preventive Maintenance (PPM) Has the Following Advantages:

- Longer lifespan: Makes VFDs and related equipment last longer.

- Energy Efficiency: Lowers energy expenses and guarantees peak performance.

- Less Downtime: Early problem identification helps to avoid unplanned failures.

- Increased Reliability: Maintains the system’s steady and seamless operation.

- Cost Savings: Reduces replacement and repair costs over time.

- Increased Safety: Reduces the chance of overheating or electrical problems.

Read about: What causes a VFD to trip?

Preventive Maintenance Schedule for VFDs

Preventive maintenance for VFDs should be performed at least once a year. Key tasks include visual inspections, cleaning, torque checks, and replacing components with limited lifespans. Thermal scans during operation help detect early signs of failure.

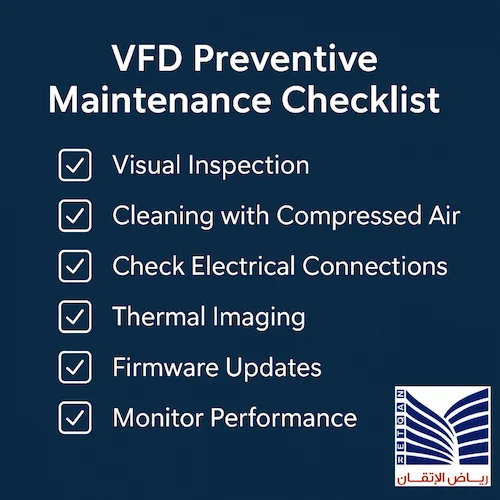

VFD Preventive Maintenance Checklist

Preventive maintenance helps facility managers detect problems early, avoid energy waste, reduce system failures, and maintain performance. This checklist covers the essential steps for keeping your VFD in top condition:

1-Visual Inspection

Look for signs of corrosion, moisture, and debris accumulation on all surfaces of the drive. Most of these issues can typically be resolved on-site with minimal equipment.

2-Cleaning with Compressed Air

Preventive maintenance primarily involves dry compressed air cleaning. Clear any accumulated dust from the vents, fans, and circuit boards inside the drive. Dust buildup can cause overheating or lead to component degradation, especially in harsh environments.

3-Check Electrical Connections

After checking the torque using a torque wrench or screwdriver, shut the system down if any connections appear hot. Avoid tightening the connectors again unless necessary. More issues than I have encountered with loose connections have been brought on by people pushing too hard on motor, power, and even control connections. Always follow the manufacturer’s torque specifications.

4-Thermal Imaging

Utilize a thermal camera to examine the variable frequency drive while it is under strain. Scanning during operation allows you to detect abnormal hot spots that may indicate electrical resistance, loose connections, or failing components. If unusual heat is detected, the unit should be shut down and inspected before restarting.

5-Firmware Updates

Programming software is used by VFDs to adjust drive parameters based on user input. For efficient functioning, precise monitoring, simplified troubleshooting, and easier startup, this program must be kept up to date.

6-Monitor Performance

Continuous performance monitoring aids in estimating the frequency of maintenance priorities, which are essential for reducing downtime. To keep maintenance professionals informed about any areas of concern, your staff should regularly examine drive performance and record their findings. Trend analysis helps identify problems before they lead to system failure.

7-Replace Critical Components

Preventive maintenance includes scheduling the replacement of components with the shortest operating life cycles to avoid unexpected failures. Critical parts such as cooling fans and capacitors naturally wear over time and must be proactively replaced before failure occurs. This approach minimizes unplanned downtime, protects the drive system’s reliability, and extends its overall lifespan.

Whether you use low voltage drives or medium voltage drives, our specialized maintenance services ensure maximum uptime and performance.

Advanced Maintenance Techniques

Advanced maintenance methods integrated with our VFD preventive maintenance checklist help optimize maintenance procedures, reduce downtime, and increase equipment dependability by utilizing technology, data analysis, and strategic planning. By using proactive and predictive methods instead of just responding to faults, these solutions go beyond simple maintenance.

Below is a summary of important ideas and methods:

● Predictive maintenance:

This method foresees possible equipment breakdowns before they happen by using data analysis and monitoring.

How it operates:

This entails monitoring equipment performance, spotting irregularities, and proactively scheduling maintenance through the use of sensors, data analytics, and machine learning. Benefits include less downtime, better maintenance plans, and lower expenses related to unplanned malfunctions.

● Condition-Based Maintenance:

Rather than following preset timetables, maintenance is carried out by the equipment’s real state.

How it operates:

Keeping an eye on the temperature, vibration, oil analysis, and other aspects of the equipment’s operation to identify when repair is required. Benefits include longer equipment life, reduced need for needless maintenance, and more effective use of resources.

● Reliability-Centered Maintenance (RCM):

An organized method for figuring out the best maintenance schedule for a given piece of equipment while taking into account its purpose, possible malfunctions, and repercussions.

How it operates:

Include choosing suitable maintenance techniques (preventive, predictive, or corrective), evaluating failure mechanisms, and identifying important components. Benefits include lower total maintenance expenditures, better equipment dependability, and optimized maintenance schedules.

● Data-Informed Upkeep:

Makes well-informed judgments on maintenance tasks by utilizing data analytics and insights.

How it functions:

Data collection and analysis from several sources (sensors, CMMS, etc.) to spot patterns, anticipate possible problems, and improve maintenance plans.

Benefits include enhanced efficiency, improved resource allocation, and better decision-making

● Additional Complex Methods:

- TPM or total productive maintenance:

Uses proactive maintenance techniques and employee engagement to increase the efficacy of the equipment.

- Systems for managing maintenance (CMMS):

Software programs that manage inventories, track work orders, expedite maintenance procedures, and offer insightful data.

- Analysis of Failure Mode and Effects (FMEA):

An organized method for determining possible system failure modes, evaluating their likelihood and seriousness, and creating mitigation plans.

By utilizing technology and data to maximize equipment performance, reduce downtime, and improve overall operational efficiency, advanced maintenance approaches essentially mark a transition from reactive to proactive maintenance.

Pro Tips for Long-Term VFD Reliability

The Best Ways to Optimize the Benefits of VFD:

1-Appropriate Installation:

To avoid overheating and preserve advantages, make sure the VFD is placed in a hygienic, well-ventilated environment. To reduce electrical interference, make use of shielded wires and appropriate grounding. You may get peak performance and preserve the long-term benefits of VFD by aligning the VFD specs with the motor requirements.

2-Observation and troubleshooting:

For long-term VFD advantages, track performance and identify early warning indicators using the integrated diagnostics and monitoring tools. To make troubleshooting easier, maintain records of system settings and error codes. Update firmware often to enhance VFD advantages, security, and operation.

Common Issues Detected During Preventive Maintenance

Let’s start by examining some of the well-known issues that managers of dependability and maintenance deal with regularly with the VFD preventive maintenance checklist.

1. Incorrect Operational Priority:

Operations often delay or cancel preventive maintenance due to concerns over equipment downtime. However, skipping maintenance increases the risk of costly breakdowns.

2. Absence of Structure and Timetable

Routine tasks without clear limits or schedules result in ineffective “tick and flick” inspections that fail to identify warning signs.

3. Reactive Behaviors

Over-scheduling maintenance as a reaction to past failures can cause unnecessary or even harmful invasive work.

4.Insufficient Coherence

Managing each piece of equipment separately wastes resources and leads to inconsistent maintenance plans and records.

5.Excessive Dependency on Prior Experience

Relying solely on opinions or historical practices without solid data can create challenges in maintenance planning.

6. Poor Instructions for the Task

Lack of detailed and accurate instructions causes poorly executed tasks and loss of expertise over time.

7. Failing to Address Specific Failure Types

Neglecting less common but high-impact failures may lead to serious problems despite routine maintenance.

8.Assumptions Regarding New Equipment

New equipment isn’t guaranteed flawless; data from similar older equipment should guide maintenance scheduling.

9.Acting on Our Capabilities Instead of Our Obligations

Selecting tasks based on team skills rather than equipment needs compromises maintenance quality; ongoing training is essential.

10.Passing Up Chances to Get Better

Without regular evaluation of completed work, tools, frequency, and instructions, maintenance effectiveness and quality deteriorate.

Why Choose R-aletqan for VFD Maintenance?

R-aletqan can help you with the installation and upkeep of VFDs in your facility. With our vast expertise in VFD preventive maintenance, our team of skilled electricians ensures your equipment is always in safe hands. We offer complete services including VFD installation, repair, and advanced maintenance methods. If you need assistance at any time of day, you can count on us. For all your VFD needs, R-aletqan is your trusted partner.

Get a free consultation today and find out how we can support your operations.

FAQs

1-Do VFDs require maintenance?

Yes, it is true that variable frequency drives, or VFDs, need to be maintained.

2-When performing preventive maintenance on a VFD?

Depending on usage and environmental factors, a Variable Frequency Drive (VFD) should have preventive maintenance done regularly, usually once a year or more frequently.

3-What is a KPI in preventive maintenance?

Measurable numbers known as Key Performance Indicators (KPIs) are used to evaluate the efficacy and efficiency of maintenance procedures meant to avoid equipment breakdowns and downtime.